Edge protection for expansion joints

Technical specifications:

materials:

pickled, hot-rolled

galvanized

stainless steel, cold-rolled, qualities V2A

and V4A

dimensions: 147mm x 297mm x 25mm

Material thickness: 3 mm

Slip resistance: R10

Weight: approx. 1,41 kg/pcs.

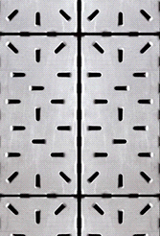

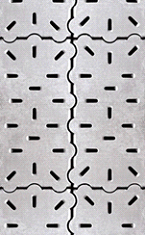

Edgetype: straight (type ST) / interlocking/intermeshing (type IG)

Technical changes reserved.

IMLTM-steel industrial floor panels measuring 15 x 30 cm are used as edge protection in the area of surface expansion joints – e.g. with screed laying. The plate is not sawn from the 30 x 30 plate, but it is punched out of one piece.

The circumferential side bar on all 4 sides of the plate ensures the stable position of the plate in the mortar bed. The arrangement of the cutouts allow a wide and stable side bar and and results in a stable corner design.

Either the variant with straight edges (type ST) or the interlocking/intermeshing variant (type IG) can be used. When using the plate type IG, the meshing of the plates allows a largely vibration-free driving crossing the expansion joints (wheel stands on two plates when crossing the joints). As a result, repair costs for floor conveyors and damage to the goods to be transported are reduced and the drivers of the vehicles are spared.

Due to the 3-sided interlocking the plate type IG (15 x 30 cm) can also be used ideally as a transition plate from an existing area laid with plates with straight edges (type ST) to an area to be laid with plates with moulded/interlocking edges (type IG).

Likewise, the panel can be used to achieve a straight finish when transitioning from a surface with type IG panels to a concrete surface.